Since, engineering simulation helps companies avoid the cost of product failure; companies are investing in creating virtual simulation platforms. Big brands are driven by great products, and great products result mainly from realistic simulation.

Traditionally, companies would design parts or subsystems in different engineering silos, and then subject their prototypes to physical tests at the later stage of product design. However, this physical testing will not give enough data for companies that produce smart products: cars, cell phones, wind turbines, etc that use thousands of components. Hence, virtual engineering simulation is increasingly preferred. Knowing how to do it is an important engineering software skill.

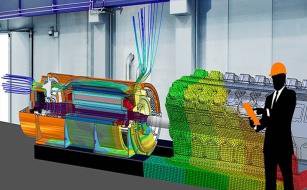

ANSYS has a whole set of products for you to perform simulation of structural aspects of a single product or complex interactions of subsystems. It will help you understand how products would work not only in ideal environments but also changing user’s environments or during unexpected consumer usage.

ANSYS offers a suite of engineering simulation software for engineers and designers to virtually analyze how their products (and thousands of parts in them) work in real world environment, at an early stage of product design. ANSYS software is being used across a wide range of industries to analyze various performance parameters such as signal integrity, electromagnetic interference, thermal issues, and mechanical failure.

The objectives of the programme are:-

The key areas to be deliberated in the programme are:

26 – 28 April 2021